Variable speed inverter based generators offer significant reduction in audible noise and fuel consumption. Most consumer quality, constant speed generators that typically run at 3600 rpm are noisy and consume much more fuel.

- The small inverter generators are well suited for Field Day due to their lower acoustic noise profile, provided their AC output is filtered to eliminate RF noise typically occuring in the 80m band.

- Using short AC cords with no filter on an inverter based generator still presents unacceptable noise on 80M.

- With no filter, detectable noise on the 40m through 10m bands was not found with the Honda generator shown in the next article below.

- The RF noise filter in the next article using 3 large 4″ OD Fair-rite mix 31 toroid cores has been proven in a series of EMI test configurations to be effective in eliminating inverter generator noise. The complete, enclosed filter including a GFCI outlet with in-use rated cover for outdoor use, costs around $150 to build.

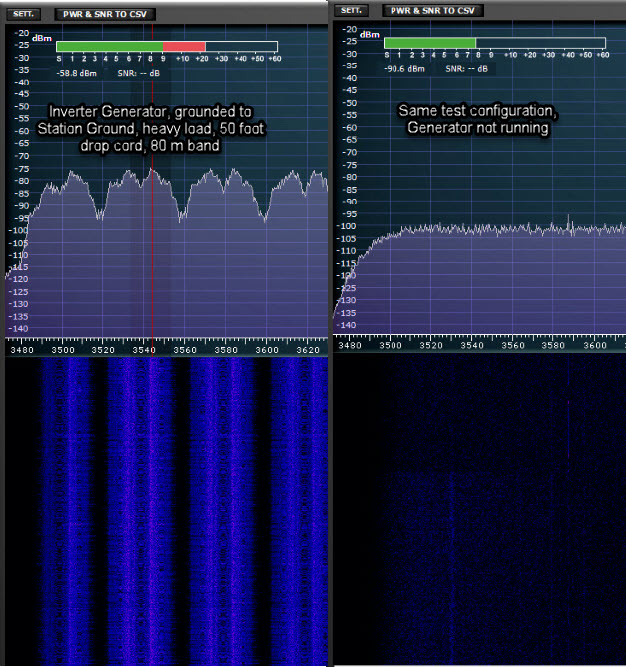

The degree of interferenence to an 80m station from an inverter based generator & attached cord radiated RF noise coupling into the Field Day antenna will vary somewhat based on the station physical arrangement. The graphs below are the received signal into an 80M station antenna located up 55 feet in the air, with a 50 foot drop cord lying on the ground underneath a portion of the antenna that connects the generator to the load.

Thinking about running your Field Day station directly off a generator and not using batteries?

There has been discussion of eliminating batteries all together (as the Field Day rules permit) and run the station on a small generator. Tests should be done before Field Day with the specific AC to DC power supply and generator to be used to determine if the fluctuating loads of a CW/SSB transmitter is going to cause deep fluctuations in generator engine speed.

Why would one care? Most hams know that with synchronous (aka constant speed) generators the frequency output is determined by the speed the armature is rotating, and the number of poles in the armature. What may not be known is that the raw voltage output of the generator winding varies proportionally with speed at which it passes through the magnetic field (aka armature rpm). That’s why all synchronous generators have a voltage regulator circuit that adjusts the other variable affecting voltage output, the strength of the magnetic field. The question is how well in a consumer quality generator does the voltage regulator and, the mechanical engine speed governor handle wild fluctuations in electrical load.

Rather than using mechnical speed governors, commercial large scale generators use electronic throttle control systems for more precise control of engine speed by comparing generator output frequency to the throttle controller’s internal 60Hz frequency standard.

Rather than expose expensive radios and DC power supplies to such effects, one fix could be to still use a battery or two in the 12VDC circuit to buffer the generator from the wildly fluctuating loads such as a CW transmitter.